Which pallet truck repairs can you carry out yourself?

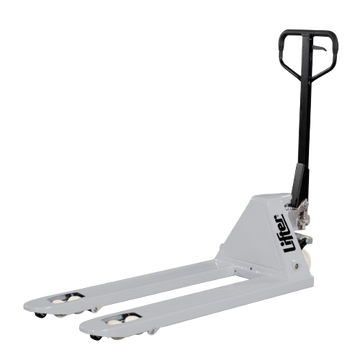

Pallet trucks are valuable helpers when heavy loads or bulky transport containers need to be moved. They facilitate work in sales areas and warehouses and rarely break down thanks to their robust design. With proper handling and regular pallet truck maintenance, industrial trucks can usually be used for a long time without any problems.

Occasionally, however, this type of equipment may develop issues, for example, when the truck does not lower or cannot be manoeuvred as usual. This can pose safety risks during operation. However, before you hire a specialist repair technician, you can carry out simple repairs yourself, such as bleeding the hydraulic system as part of a regular pallet truck inspection. Read on to learn more about pallet truck repair and maintenance.

Many of the issues that occur on pallet trucks can usually be quickly repaired. This applies especially to hand pallet trucks with hydraulic lifts. However, in the case of damage that is more complex or that affects the electrical components on an electric pallet truck, you should always commission a specialist technician or repair centre. In accordance with the regulations of the trade associations, and also the manufacturers, such work may only be carried out by trained and certified specialist personnel. Only in this way can the functionality and operational safety be properly restored.

Attention!!!! Damage or functional faults that can be repaired by the user often affect the mechanical components of hand pallet trucks. This usually involves the hydraulics or the seals.

1. Hydraulic repair of pallet trucks

If the lift truck can no longer be lowered or no longer pumps up, it is usually a problem with the hydraulics system. This can be for reasons such as:

- Air in the hydraulics system

- Foreign bodies or impurities in the hydraulics system

To ensure trouble-free operation, you should therefore regularly bleed the hydraulic system of the pallet truck. To do this, unload the pallet truck and move the fork handle to the lowering position and pump vigorously several times. If this quick procedure is not sufficient, you can release the air via the hydraulic cylinder bleed screw located directly on the hydraulic cylinder. However, the bleeding procedure may vary depending on the model.

Contact us and our expert staff will be happy to help you with this.

If hydraulic oil escapes through leaking lines or cylinders, however, these must be replaced at a specialist workshop. Damage to the hydraulic pump must also not be repaired by the customer but must be handed over to the appropriate specialist personnel for repair.

2. Top up or change the oil

If bleeding air from the hydraulics system did not improve the situation, the oil level is probably too low or the hydraulic oil is contaminated, meaning that the lift truck no longer lifts or lowers. In this case, you should check whether the oil level complies with the manufacturer’s specifications and top up the oil accordingly.

Occasionally, however, the mechanical malfunctions are not due to the quantity of hydraulic oil, but to the condition of the oil. Impurities or foreign bodies in the oil can get into the spaces between cylinders and pistons and damage the hydraulic system here. In this case, the oil must be replaced completely. Drain the old oil completely via the drain plug on the oil tank of the lift truck and dispose of it in the waste oil disposal. Then refill with fresh hydraulic oil until the level reaches the specified mark.

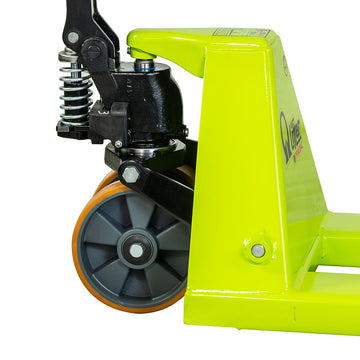

3. Pallet truck repair – replacing wheels and rollers

If the pallet truck does not transport loads in a stable manner, despite perfect bearings, or if the vehicle cannot be manoeuvred as usual, this may be an indication of worn or damaged transport rollers. You can easily replace the rollers yourself. Ideally, you will already have suitable wheels and load rollers for transport equipment on hand, however, ordering replacement castors in the appropriate size and load compatibility is usually easy. If possible, select original parts for this purpose, as only these are optimally compatible with your lift truck, ensuring trouble-free operation.

If the pallet truck still behaves sluggishly or remains difficult to manoeuvre during load transport, even after the rollers have been replaced, the fault usually lies in a defective chassis. The repair work for this should not be carried out by yourself under any circumstances, but only by a specialist workshop.

See our Pallet Truck Steer Wheel Replacement Guide

See our Pallet Truck Load Roller Replacement Guide

Pallet truck inspection checklist: testing the pallet truck

Regular checks of the pallet trucks and other material handling equipment ensure that they are in perfect condition and that your employees can work safely and efficiently. The checks can also quickly determine if the lift truck needs repair. In the long run, regular inspection of your pallet trucks will also increase service life in the plant. For a legally compliant inspection of the trucks, an inspection should be carried out once a year by a specialist. The following functions and technical conditions should be checked at least once a week:

- Inspect condition and functionality of wheels

- Test Lift/ Lower Handle

- Check for worn handle pins

- Check for any hydraulic oil leaks

- Check for worn handle pull chain linkage

- Are there any obvious damages, cracks, or deformations on the pallet truck?