How to operate a hand pallet truck safely

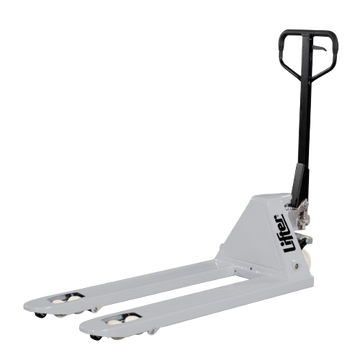

The hand pallet truck, sometimes known as a pump truck, pallet jack or manual pallet truck is a cornerstone of the materials handling industry.

Operating manual equipment correctly is vital to warehouse and operator safety. So, what is a hand pallet truck and how do you use it? BCF Handling can help you get to grips with pallet trucks!

What does a hand pallet truck do?

Hand pallet trucks are designed to quickly lift palletised loads and move them from one point to another. By using a hand pallet truck you are reducing the need to manually lift and carry loads, which in turn increases the productivity and efficiency of moving loads around your warehouse or workspace.

Pre-operational checks

- Check you have the correct type of hand pallet truck for your operation. For example, make sure the fork length and width is suitable for the load you want to move. BCF Handling can advise what truck you require for your needs – contact us for assistance. Also check out our range of pallet trucks here.

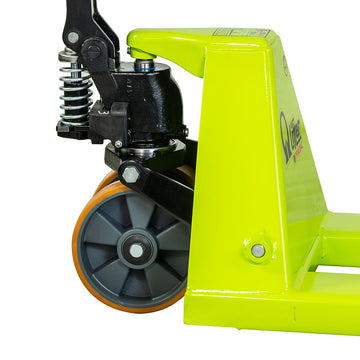

- Visually inspect the truck for wear or damage.

- Raise the forks fully to check there is no sign of hydraulic oil leaks. You can do this by pressing the lever downwards then operating the handle.

- Check the load is securely stacked.

- Check there is no damage to the pallet.

Setting up

- Align the forks with the gaps of the pallet.

- Firmly grip the handle with two hands and, in the up-right position, push steadily forwards, carefully guiding the forks into the gaps.

- Ensure there is enough clearance before raising the forks; be aware of any overhead obstructions and any width restrictions.

- Raise the forks using the lever. Once the pallet is clear of the floor, return the lever to the neutral position.

- Push the handle down, turn to face the direction you will be travelling and grip the handle firmly. If you are turning left, use your left hand, when turning right, use your right hand.

Moving your pallet truck safely

- Ensure your route is clear of obstructions; check there are no pedestrians or other trucks.

- With the handle low, gently pull to start the truck moving. The forks should be trailing behind you.

- Walk to one side of the truck. Never stand directly in front of the pallet truck when travelling and never stand on the inside of a turn.

- Where possible, travel on the left side of the aisle and do not make sharp turns.

- Always walk at a safe speed. Never run.

- If travelling down a slope with a loaded truck, keep the load facing down and control the speed by pulling back with both hands on the handle.

At your destination

- Once at your destination, manoeuvre the load into position.

- Ensure you are clear of the load and slowly pull on the lever to lower the load under control.

- When fully lowered, release the lever into the neutral position.

- Check your surroundings. If it is clear, stand to one side and carefully pull the hand pallet truck away from the pallet.

- Make a final check for any new damage of the pallet, the load and thehand pallet truck.

Extra considerations

Some people see manual hand pallet trucks as disposable items. However, if they are correctly maintained and serviced they will require less frequent replacement. Often, repairs can be easily made, and BCF Handling can offer advice for what parts you require and how to complete repairs. However, we have a network of reliable and experienced team of hand pallet truck specialists throughout the UK, Northern Ireland and Ireland who can repair, service and maintain all makes of hand pallet trucks for you.

This helps to ensure that your hand pallet truck not only works safely, but can also extend the expected operating life of the truck too.

If you have any safety enquiries about any of your material handling equipment, or assistance with ordering replacement parts for your pallet truck, please contact us.